About decanter centrifuge

Features of decanter centrifuge

* Possible flexibly operating against slurry condition changes

* Easy maintenance

* Easy Operation

* Stable dewatering

* Possible continuous processing

* Small foot print

* Sealed structure to prevent leakage odors and toxic gases

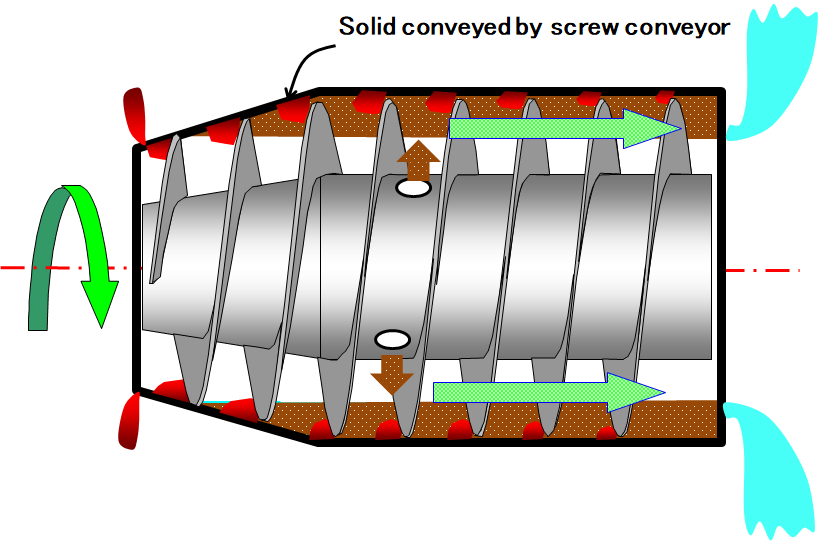

Decanter separation mechanism

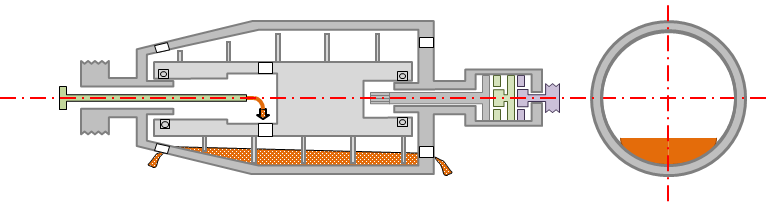

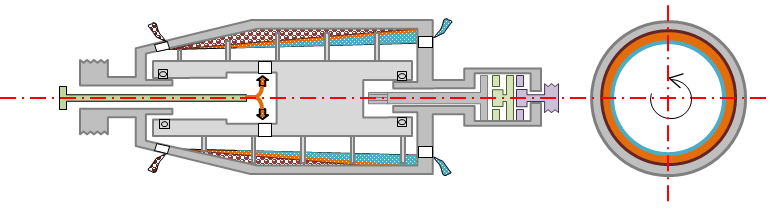

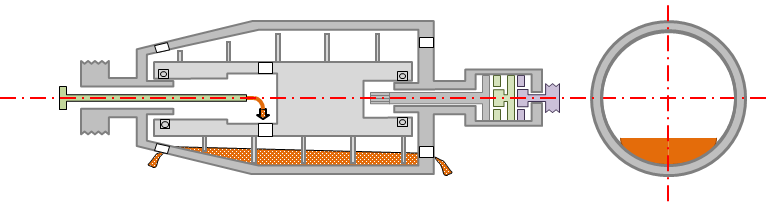

(1) Gravitational condition

In gravitational condition, liquid is settling in the bottom of bowl.

(2) Centrifugal force field

In centrifugal force field, liquid and sold are settling all around inside of bowl by evenly.

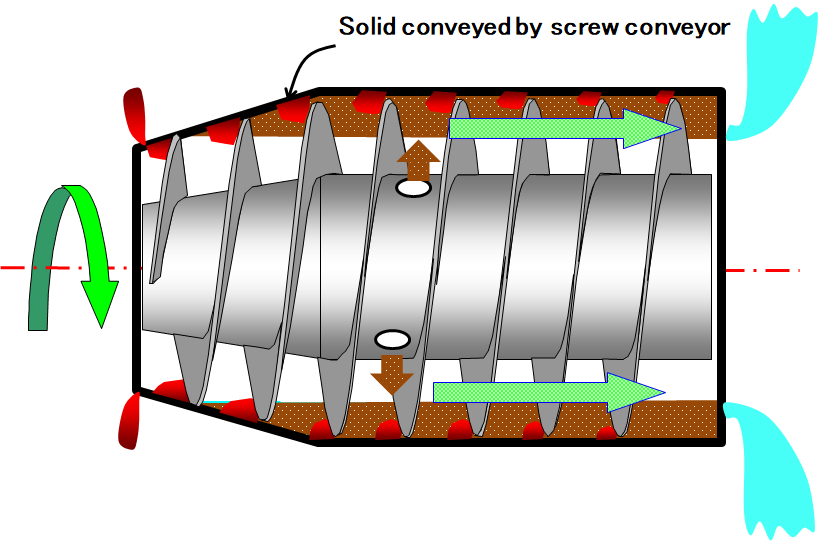

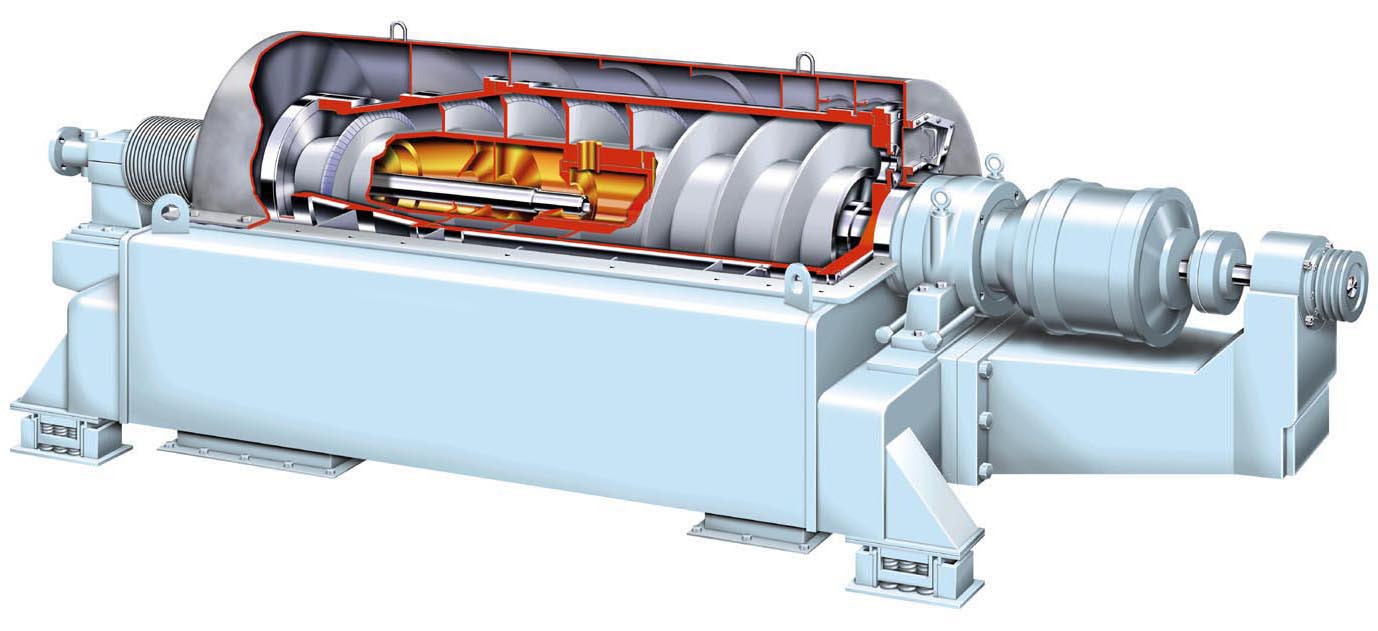

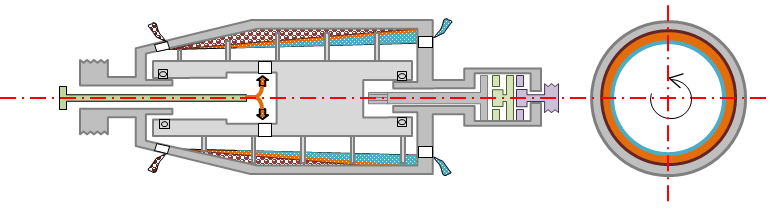

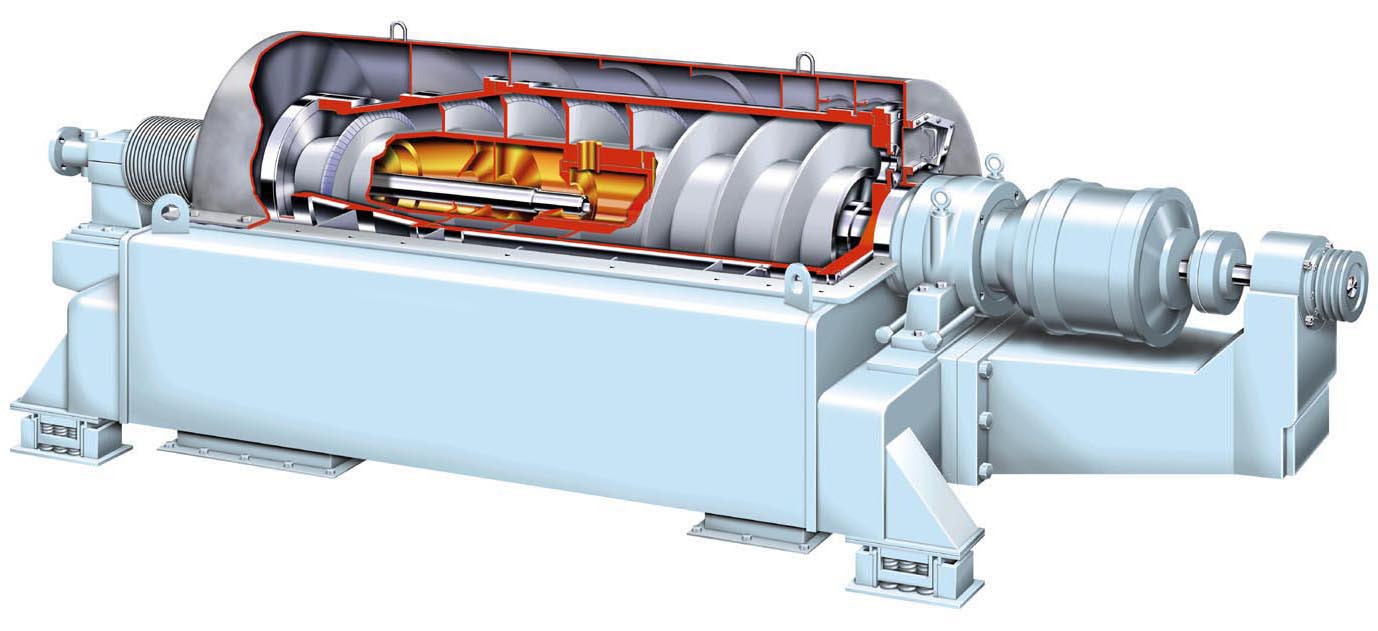

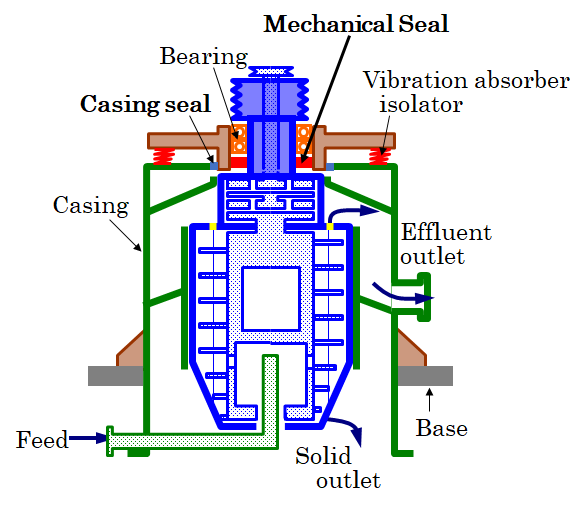

Horizontal decanter

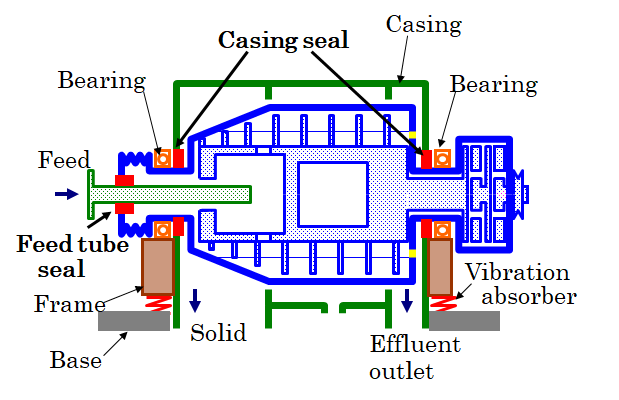

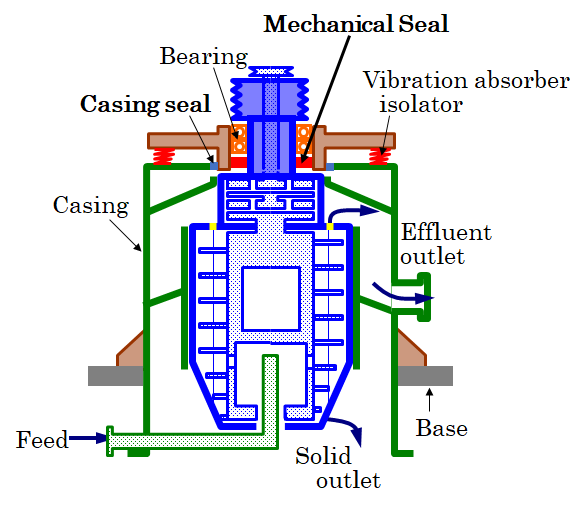

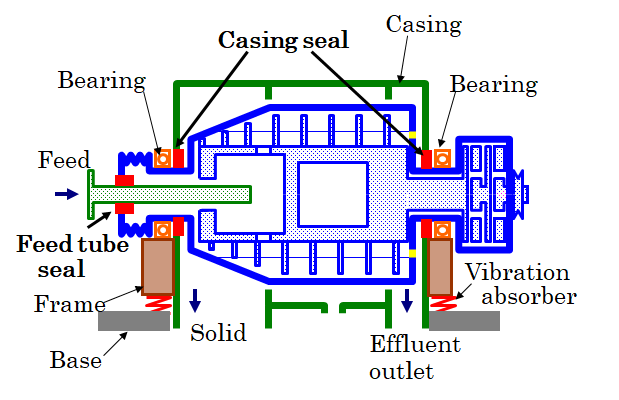

Sealed three location

All seales are having chance to contact feed material.

Continuous separation is possible, and possibel stable performance for a long period of time. Moreover, it is easy to operate and can be unmanned operation.

We pursued economic efficiency and realized cost reduction. Since it is a space-saving design, the installation area can be small.

The main applications include "separation and dewatering of solids", "clarification and separation of liquids", and

"classification of solids" of mixtures of solids and liquids, as well as separation of mixtures of liquids and liquids.

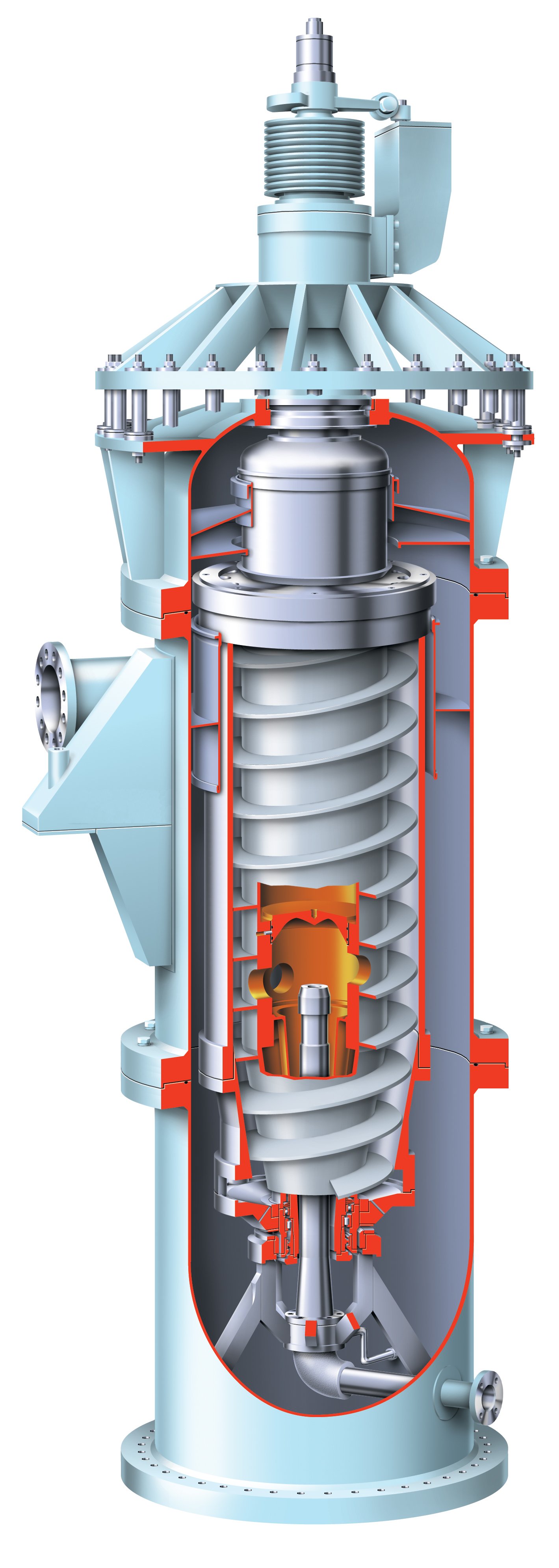

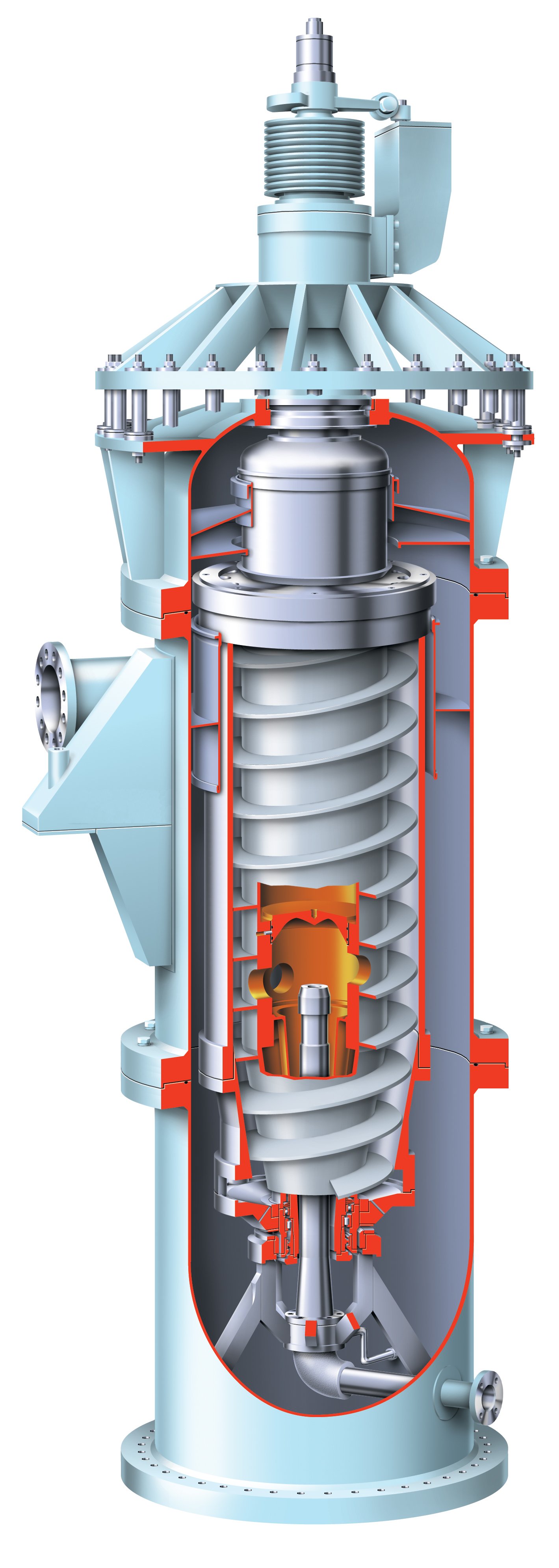

Vertical decanter

(Pressurized)

Single sealed design

Max. pressurized up to 1 MPa (10 kg/cm2).

Due to the vertical structure using a mechanical seal, it is able to pressurized design, it can be separated even under high-pressure conditions.

It is also a big advantage that it does not take up an installation area. Designed for efficient separation even under harsh conditions for exapmle chemical plants,

<solid-liquid> separation of organic solvents slurries, catalyst recovery, coal liquefaction, heavy oil, waste. It is effective for <solid-liquid> separation at high temperature and

high pressure. We also have a lineup of HT types that can be processed at high temperatures up to 350 ° C.